In April 2024, the Environmental Protection Agency (EPA) announced the first-ever national, legally enforceable drinking water standards for per- and poly-fluoroalkyl (PFAS) substances. Also known as “forever chemicals,” studies have shown links between PFAS and liver damage, thyroid disease, immune system changes, developmental effects or delays in infants and children, higher rates of certain cancers and higher cholesterol levels.

Water districts must comply with these new federal guidelines to avoid legal penalties. Be sure to catch up on what you may have missed with our guide to the new federal PFAS regulations.

The Timeline for Testing and Treatment

All public water systems must complete initial testing for PFAS chemicals by 2027, followed by ongoing compliance monitoring. If testing finds PFAS levels that exceed the legal standards, the individual water districts must notify their customers and act to reduce the levels of PFAs in the drinking water by 2029.

Public Awareness Applies Pressure to Act Now

Interest in PFAS chemicals has skyrocketed as the public becomes more informed of their harmful, lasting health effects. Media coverage has been extensive, from local news stations across the country to major national publications such as USA Today, Bloomberg Law, Associated Press, Vox, NBC News, ABC News and others. The public has also been scouring the internet for information, with statistics showing thousands of Google searches about how to avoid PFAS each week. In short, residents are aware—and they’re demanding action.

New Grant Program Available for Small and Disadvantaged Communities

The EPA has recognized that communities need help addressing PFAS contamination in drinking water and has allocated $5 billion in grant programs for small or disadvantaged communities. This transformational funding has been provided to:

– Address PFAS and emerging contaminant challenges.

– Target resources to communities most in need of assistance to ensure that no community is left behind with unsafe, inadequate water.

– Advance equity and environmental justice by educating communities about funding opportunities and simplifying administrative procedures to reduce or eliminate barriers to access funds.

PFAS testing and treatment can be complex and take several months to complete. While it may sound like districts have ample time to comply with the new regulations, delaying action can risk access to grant funds and increase the likelihood of getting stuck in the backlog that waiting until the last minute can cause.

Be sure to visit the Emerging Contaminants in Small or Disadvantaged Communities page for more information about the grant program.

How RK Water Can Help

This may all sound overwhelming, but RK Water is here to support you through the entire process. We can:

– Perform initial PFAS sampling and testing.

– Identify and evaluate the PFAS compounds requiring treatment and identify the appropriate treatment method.

– Evaluate site-specific conditions, sustainability of the treatment method and cost-effectiveness of viable treatment options.

– Perform CAPEX vs. OPEX evaluation of competing treatment options.

– Design, procure and install temporary or long-term treatment system equipment.

– Operate and maintain treatment systems.

– Provide compliance testing and reporting.

– Handle media change-outs and disposal management.

Are you ready to take advantage of free government funds, get legally compliant and share that you’re at the forefront of public safety? Contact RK Water and save your spot today!

Interest in per- and poly-fluoroalkyl (PFAS) substances in drinking water has skyrocketed as the public becomes more aware of their harmful, lasting health effects. Also known as “forever chemicals,” studies have shown links between PFAS and liver damage, thyroid disease, immune system changes, developmental effects or delays in infants and children, higher rates of certain cancers and increased cholesterol levels. Media coverage has been extensive, from local news stations across the country to major national publications such as USA Today, Bloomberg Law, Associated Press, Vox, NBC News, ABC News, MSN, Washington Examiner and many others.

In April 2024, the Environmental Protection Agency (EPA) took initial steps to address this issue by announcing the first-ever national, legally enforceable drinking water standards for PFAS substances, known as Maximum Contaminant Levels (MCLs.) While the EPA has allowed three years for water districts to conduct testing and an additional two years to complete remediation efforts if PFAS is found, the shouts from the public are already loud and will only continue to grow. Property managers of large, multi-residential buildings should consider how the public outcry can influence their property’s standing with potential and existing residents now.

What Can Property Managers Do?

Building owners or property managers can test their building’s drinking water for PFAS and install whole-building treatment systems. Proactively addressing PFAS before national law requirements go into effect can enhance the property’s reputation as health-conscious, socially responsible and environmentally friendly. Management’s willingness to address PFAS can even be a deciding factor when potential residents evaluate residential complexes that may otherwise be similar.

Common Methods for Filtering PFAS

Effective filtration is critical for mitigating PFAS contamination in drinking water. Let’s take a look at the various filtering methods property managers can use as well as the pros and cons of each.

Activated Carbon Filtration

Activated carbon filters are effective in removing chlorine, chloramines, volatile organic compounds (VOCs), and other contaminants that affect water taste and odor. In certain instances, carbon filtration can also be a key treatment method for the reduction of PFAS.

Pros:

– Effectiveness: Activated carbon is highly effective at removing long-chain PFAS compounds.

– Availability: Widely available and used in many types of water filtration systems.

– Cost: Generally affordable compared to other advanced filtration methods.

– Disposal: Can be regenerated and reused, reducing long-term costs and eliminating disposal.

Cons:

– Short-Chain PFAS: Less effective at removing short-chain PFAS compounds.

– Empty Bed Contact Time (EBCT): Requires longer contact time with the water to be treated resulting in larger footprint compared to ion exchange resin

– Maintenance: Requires regular replacement to maintain effectiveness.

– Limited Capacity: Can become saturated with contaminants, reducing treatment efficiency over time.

Ion Exchange Treatment

Ion exchange filters are effective in removing PFAS from drinking water. The benefit of ion exchange resin for PFAS treatment is the smaller footprint required compared to activated carbon filtration.

Pros:

– High Efficiency: Capable of removing both long- and short-chain PFAS compounds.

– Empty Bed Contact Time (EBCT): Shorter contact time with the water to be treated compared to activated carbon

– Foot Print: Smaller footprint required compared to activated carbon

Cons:

– Initial Cost: Potential for higher initial investment compared to activated carbon.

– Disposal: Cannot be regenerated, and will likely require special disposal considerations including incineration

Reverse Osmosis (RO)

RO systems use a semi-permeable membrane to remove dissolved solids, heavy metals and other impurities at the molecular level, providing highly purified water.

Pros:

– Comprehensive Removal: Effective against a wide range of contaminants, including all PFAS compounds.

– High Efficiency: Capable of removing over 99% of PFAS.

Cons:

– Cost: Expensive installation and maintenance.

– Waste Stream: Produces a significant amount of wastewater. A rule-of-thumb is 30% of the volume treated will be wasted.

– Disposal: Wastewater consists of concentrated PFAS compounds requiring management and/or disposal

– Maintenance: Membrane requires regular replacement and system maintenance.

Nanofiltration

Nanofiltration is similar to reverse osmosis, but uses membranes with slightly larger pores. It effectively removes PFAS while allowing beneficial minerals to remain in the water.

Pros:

– Effectiveness: Removes a high percentage of PFAS.

– Mineral Retention: Retains essential minerals in drinking water.

– Energy Efficiency: Generally requires less energy than reverse osmosis.

Cons:

– Cost: Still relatively expensive compared to more basic methods.

– Maintenance: Membranes need periodic replacement and care.

– Selectivity: May not remove all contaminants as effectively as reverse osmosis.

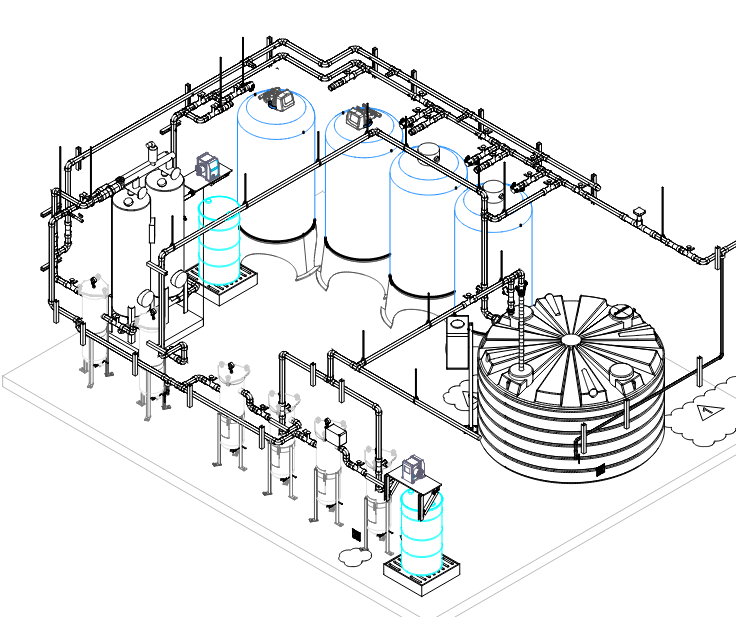

Whole Building Water Treatment Installation

Water is a fundamental necessity for any building, be it residential, commercial or industrial. Ensuring the water quality is safe and suitable for all intended uses – drinking, bathing, cooking, cleaning, or manufacturing – is crucial. Whole building water treatment installation addresses this need by providing a comprehensive system that purifies and conditions the water supply for an entire building.

Whole building water treatment systems are designed to treat all the water entering a building, providing a centralized solution to address water quality issues. These systems typically include a combination of filtration and purification technologies to remove contaminants, improve water taste and odor, and ensure compliance with health standards. Key components of a whole building water treatment system may include:

– Pre-Filtration: The initial stage involves removing larger particles such as sand, silt, and sediment from the water. Pre-filters protect subsequent treatment stages from clogging and reduce the load on them.

– Filtration: Using one of the methods discussed above.

– Post-Filtration: The final stage may include additional polishing filters to remove any remaining fine particles or impurities, ensuring the highest water quality.

The benefits of whole building water treatment are improved water quality and health benefits. Comprehensive treatment systems ensure that all water entering the building is clean, safe and free from harmful contaminants. By removing harmful chemicals, these systems protect the health of building occupants.

Considerations for installation include water quality assessment, system sizing, professional installation, maintenance requirements and compliance with regulations. Investing in a whole building water treatment system is a proactive step toward ensuring high-quality water for all uses within a building. By addressing water quality issues comprehensively, these systems provide numerous benefits including environmental sustainability. Proper assessment, sizing and professional installation are key to maximizing the benefits of these systems, making them a valuable addition to any building.

How RK Water Can Help

Effective testing, treatment and monitoring are critical, yet as you’ve seen, there are so many options! Which filtering method you need can differ between buildings or complexes depending on the types of PFAS that are present, maintenance considerations, and more. Luckily, you have a friend in the business who can support you through the entire process. RK Water can:

– Perform initial PFAS sampling and testing.

– Identify and evaluate the PFAS compounds requiring treatment and identify the appropriate treatment method.

– Evaluate site-specific conditions, sustainability of the treatment method and cost-effectiveness of viable treatment options.

– Perform CAPEX vs. OPEX evaluation of competing treatment options.

– Design, procure and install temporary or long-term treatment system equipment.

– Operate and maintain treatment systems.

– Provide compliance testing and reporting.

– Handle media change-outs and disposal management.

Are you ready to leverage a significant differentiator to help market your property and be at the forefront of enhancing public safety? Contact RK Water today!

In April 2024, the Environmental Protection Agency (EPA) announced the first-ever national, legally enforceable drinking water standards for per- and poly-fluoroalkyl (PFAS) substances. Known as “forever chemicals,” PFAS poses significant risks to public health. Studies have shown links between PFAS and liver damage, thyroid disease, immune system changes, developmental effects or delays in infants and children, higher rates of certain cancers and higher cholesterol levels. The clock has started for water districts to act and protect public health by providing safe, clean drinking water that abides by the new enforceable PFAS limits.

The New PFAS Limits

Restrictions have been imposed for five individual PFAS: PFOA, PFOS, PFNA, PFHxS and HFPO-DA (also known as “GenX Chemicals.”) There are also rule limits for mixtures of any two or more of four types of PFAS: PFNA, PFHxS, PFBS and “GenX Chemicals.” See the chart below for specific level requirements. The enforceable limits are represented by Maximum Contaminant Levels (MCLs), while the Maximum Contaminant Level Goals (MCLGs) are health-based and non-enforceable.

| Compound | Final MCLG | Final MCL (Enforceable Levels) |

|---|---|---|

| PFOA | 0 | 4.0 parts per trillion (ppt) |

| PFOS | 0 | 4.0 ppt |

| PFHxS | 10 ppt | 10 ppt |

| PFNA | 10 ppt | 10 ppt |

| HFPO-DA (“GenX Chemicals”) | 10 ppt | 10 ppt |

| Mixtures containing two or more of PFHxS, PFNA, HFPO-DA and PFBS | 1 (unitless) Hazard Index | 1 (unitless) Hazard Index |

The Timeline for Testing and Treatment

All public water systems must complete initial testing for PFAS chemicals by 2027, followed by ongoing compliance monitoring. Beginning in 2027, public, regulated water districts are responsible for informing the public of the levels of PFAS measured in their drinking water on an ongoing basis.

If testing finds PFAS levels that exceed the legally required standards, the water district must notify the public and act to reduce the levels of PFAS in the drinking water by 2029.

How You Can Test for PFAS and Get Compliant

Technological developments such as granular activated carbon, reverse osmosis and ion exchange systems can filter PFAS appropriately. The EPA has allocated $1 billion to help water districts resolve PFAS in the drinking water, and districts have the flexibility to determine the best solution for their community.

While this all may sound overwhelming, RK Water is ready to support you through the entire process. We can:

– Perform initial PFAS sampling and testing.

– Identify and evaluate the PFAS compounds requiring treatment and identify the appropriate treatment method.

– Evaluate site-specific conditions, sustainability of the treatment method and cost-effectiveness of viable treatment options.

– Perform CAPEX vs. OPEX evaluation of competing treatment options.

– Design, procure and install temporary or long-term treatment system equipment.

– Operate and maintain treatment systems.

– Provide compliance testing and reporting.

– Handle media change-outs and disposal management.

If you’re ready to be at the forefront of enhancing public safety, contact RK Water today!

Additional Resources from the EPA

FAQs for Drinking Water Primary Agencies

In the modern world, access to safe and clean water is fundamental to public health and overall well-being. In the early 1900’s, Chlorination emerged as a water treatment process that revolutionized how we purify and disinfect water on a large scale. The impact of chlorination on society has been profound, drastically reducing waterborne diseases and saving countless lives. In this blog, we will dive into the science behind chlorination, understanding how this ubiquitous disinfection method works to safeguard our water supply.

The Need for Water Treatment

Before the advent of water treatment, communities were plagued by waterborne illnesses such as cholera, E.coli, typhoid and dysentery. These illnesses could and did spread rapidly, devastating entire populations. To address these public health concerns, two pioneering individuals developed the first water treatment plant to establish the delivery of safe drinking water to homes and businesses.

Chlorination is a Game-Changing Discovery

In 1908, a monumental breakthrough occurred when bacteriologist John L. Leal and engineer George W. Fuller introduced the practice of chlorination at the Jersey City Water Supply Company’s Boonton Reservoir in Jersey City, New Jersey, in the first large-scale chlorination of a public drinking water supply in the United States. Initially met with opposition from city officials and the public based on adding “poisonous” chemicals to the drinking water supply, Leal and Fuller persisted, convinced of the potential benefits to the public.

This marked the beginning of an era that would significantly alter the landscape of water purification and serves today as the basis for water treatment purification. By the 1920s, chlorination was a well-established primary means of disinfecting drinking water nationwide.

Today, millions of Americans have access to safe, affordable and abundant drinking water filtered and safely treated with chemical disinfectants due to Leal’s and Fuller’s pioneering engineering triumph.

Mechanism of Chlorination

Chlorination involves the addition of chlorine, either in the form of chlorine gas, sodium hypochlorite (liquid bleach), or calcium hypochlorite (solid granules), to water sources. Upon introduction, the chlorine reacts with various organic and inorganic substances in the water.

Formation of Hypochlorous Acid (HOCl):

Chlorine gas reacts with water (H2O) to form hypochlorous acid (HOCl) and hydrochloric acid (HCl). Hypochlorous acid is the active and most effective form of chlorine for disinfection.

Cl2 + H2O → HOCl + HCl

Disinfection Process:

Hypochlorous acid acts as a powerful disinfectant, attacking and destroying harmful microorganisms by penetrating their cell walls and interfering with enzymatic processes essential for survival. This disrupts the microorganisms’ ability to reproduce and spread, effectively neutralizing the threat of waterborne pathogens.

Chlorine Residual:

Maintaining a chlorine residual in the treated water is crucial to ensure continuous disinfection throughout the distribution system. A chlorine residual refers to the small amount of chlorine that remains in the water after the initial treatment. This residual concentration is a protective barrier against potential contamination during water distribution.

Challenges and Concerns

While chlorination has been a transformative and life-saving water treatment technique, some challenges and concerns are associated with its use.

Disinfection Byproducts (DBPs)

The reaction of chlorine with organic matter in water can lead to the formation of disinfection byproducts (DBPs), such as trihalomethanes (THMs) and haloacetic acids (HAAs). Some DBPs have been linked to potential health risks, including an increased risk of cancer. To address this, water treatment facilities have implemented strategies to minimize DBP formation.

Chlorine Resistance

In recent years, certain microorganisms have shown varying degrees of resistance to chlorine, making it necessary to explore alternative disinfection methods or combine chlorination with other treatment processes.

Conclusion

The science behind chlorination has revolutionized public health by providing access to safe and clean water on a large scale. The disinfection power of chlorine has proven pivotal in reducing waterborne diseases and preventing epidemics. Although challenges persist, ongoing research and advancements in water treatment technology will continue to refine the chlorination process, ensuring that future generations enjoy the benefits of safe and potable water.

Visit rk-water.com for more information.

At RK Water, we specialize in providing custom water treatment systems to meet the unique needs of our clients. We take care of every part of the fabrication process, from identifying treatment needs to delivering a fully functional operational water treatment system.

Identifying Water Treatment Needs, Goals and Approach

Every custom water treatment project begins with a thorough assessment of site-specific treatment requirements. By understanding our client’s needs, we design comprehensive water treatment solutions that align with desired outcomes. This includes considering contaminant levels, flow rates, and water quality standards. Our team will engineer a system that meets or exceeds desired standards to meet environmental regulations. Based on the needs and treatment goals, RK Water will explore the best available technologies, such as reverse osmosis, medias, resins and chemical treatment.

Creating Schematic Design and CAD Fabrication Drawing

With the treatment approach determined, our experienced engineers create a schematic design that serves as a blueprint, outlining the treatment system’s layout, equipment arrangement and process flow. Using cutting-edge CAD software, RK Water generates detailed drawings of the fabrication process. These drawings provide precise specifications for each component, including dimensions, materials, connections and assembly instructions.

Procurement, Fabrication and Testing

Our in-house team of plumbers and pipefitters will fabricate the designed water treatment systems. By working with other RK business units, we have the in-house capabilities and facilities to ensure every component is installed correctly and according to the design specifications. Once fabrication is complete and signed off, the completed fabricated system is carefully packaged and prepared for shipping to the installation site.

Operational Treatment System

If desired, the RK Waters field team will install the treatment system upon arrival at the site. Before system operation begins, we’ll ensure that all components are properly connected and calibrated, guaranteeing a smooth start-up sequence. Furthermore, RK Water offers ongoing operational and maintenance services, including technical assistance, to keep the treatment system operating at peak performance.

At RK Water, we understand that each water treatment project is unique and requires a tailored approach. Our fabrication process ensures that our clients’ water treatment goals are effectively and efficiently achieved. If you’re looking for a reliable partner in water treatment, count on RK Water to provide comprehensive solutions.

Learn more at rk-water.com.

PFAS, also known as per- and polyfluoroalkyl substances, are thousands of chemicals belonging to a single chemical class. PFAS contaminants are found in drinking water as a result of industrial releases and the use of firefighting foam. However, PFAS may also be used in a wide range of products, from food packaging to stain-resistant furniture, and our exposure comes from multiple sources and routes. PFAS does not break down in the environment and moves through soil to drinking water, which is why many scientists refer to them as “forever chemicals.”

What products contain PFAS?

Everyday products may be made with PFAS compounds, such as:

• Clothing like raincoats, yoga pants, shoes and accessories

• Paper packaging, including microwave popcorn bags and takeout packaging

• Stain-resistant carpets, rugs and furniture

• Non-stick cookware

• Firefighting foams and ski wax

Exposure to PFAS is virtually everywhere, from food, air and water, resulting from manufacturing releases and use of PFAS-containing products. Fortunately, the United States Environmental Protection Agency (EPA) has been taking active steps to update drinking water health advisories to replace those issued in 2016. The updated advisories indicate that some adverse health effects occur with concentrations of PFAS in water near zero and below the EPA’s ability to detect. Essentially, the lower the level of PFAS chemicals, the lower the risk to public health.

In addition, EPA is encouraging states, drinking water utilities, and community leaders that find PFAS in their drinking water to inform residents, undertake additional monitoring to assess the level, scope, and source of contamination, and examine steps to reduce exposure. Individuals concerned about levels of PFAS in their drinking water should consider actions that may reduce exposure, including installing a home or point-of-use filter.

How to reduce PFAS contamination?

Under the State of Colorado’s guidance, over 100 communities are retesting drinking water to create dilution or treatment plans if PFAS levels are high. The EPA’s drinking water guidance for PFAS was formerly no more than 70 parts per trillion. However, in June 2022, the EPA’s guidance for two forms of PFAS, PFOA and PFOS, was cut to 0.004 parts per trillion and 0.02 parts per trillion, respectively.

While the EPA has only proposed guidelines for PFAS levels in drinking water, states across the country are implementing enforceable drinking water standards and pursuing litigation against manufacturers of PFAS chemicals for contaminating water supplies and other natural resources.

With more data being shared with government entities about PFAS contamination and states adopting more policies to protect their residents, restrictions will get more rigorous to help eliminate PFAS chemicals. Local governments, state governments and businesses need to work together to help protect those in their communities by taking proper action now.

PFAS Chemical Treatment and Disposal

RK Water has the knowledge and expertise to guide your business through treatment selection, system sizing and ongoing operation. As water treatments experts, RK Water will:

• Perform initial PFAS sampling and testing through DOD certified laboratories

• Evaluate the characteristics of the PFAS requiring treatment

• Take into account site-specific conditions, sustainability of the treatment methods, and cost-effectiveness of viable treatment options

• Perform CAPEX vs. OPEX evaluation of competing treatment options

• Design and install temporary or long-term equipment, including treatment media

• Operate and maintain equipment and treatment systems, including media changeouts

• Compliance testing and reporting

• Manage disposal of media

The result is the reliable treatment of PFAS contamination to desired treatment goals. RK Water has you covered with in-house technical expertise. As RK Water is not committed to one proprietary product line, you are ensured that you will receive the best treatment options available in the market and client-focused attention throughout the process.

Learn more about RK Water’s PFAS treatment services.

Written by Ileana Morales

EPA Announces New Drinking Water Health Advisories for PFAS Chemicals, $1 Billion in Bipartisan Infrastructure Law Funding to Strengthen Health Protections, accessed July 29, 2022, Environmental Protection Agency

Get the Facts: PFAS (per- and polyfluoroalkyl substances), accessed July 29, 2022, Safer Chemicals, Healthy Families

South Adams County water district is buying Denver’s water to dilute “forever chemicals,” accessed July 29, 2022, The Colorado Sun

By: RK Water

The use of steam boilers for industries in the U.S. is essential, especially when you consider they are used in highly monitored industries including food and beverage processing, medical facilities, power generation and sanitation. One of the main components in a successfully functioning steam boiler is the quality of its feed water.

In order to ensure proper operation of steam boilers, high purity water is required. However, through years of experience, RK Water has discovered that the single biggest issue in nonfunctioning steam boilers is poor feed water pretreatment, or, in some instances, no pretreatment at all. This leads to much larger maintenance problems.

TOP 3 REASONS FOR FEED WATER PRETREATMENT IN STEAM BOILERS

- Boiler failures result in operational downtime, repair and cleaning expenses

- Extensive scale deposits require more fuel for steam production

- Hot spots can cause boiler tube corrosion or failure

The evidence of poor pretreatment speaks volumes about the importance of having a scheduled service in place. A good boiler feed water treatment system will help you avoid costly plant downtime, expensive maintenance fees and boiler failures as a result of scaling, corrosion and pollutants in the boiler and downstream equipment.

If you suspect you are having issues with pretreatment, allow RK Water to take a sample of your feed water and run several tests to see what level of hardness is making it to your boiler. Our team can make recommendations, adjustments and even studies and analysis of your current system to see what best meets your needs.

By: RK Water

The Centers for Disease Control and Prevention (CDC) recently reported that Legionnaires’ disease nearly quadrupled in the United States from 2000 to 2015, and most cases could have been prevented with water treatment solutions to prohibit legionella bacterial growth in water.

From 2000 through 2014, legionellosis increased nearly fourfold, from .42 to 1.62 cases per 100,000 persons. The disease is contracted when a person breathes small droplets of water contaminated with the bacteria Legionella. In the past year, about 5,000 Americans were diagnosed, and more than 20 outbreaks were reported. About one in ten infected persons will die from the infection, and most require hospital care to make a full recovery.

The CDC cited that cooling towers are a common source of infection and must be properly maintained to prevent legionellosis, and they recently released a toolkit: Developing a Water Management Program to Reduce Legionalla Growth and Spread in Buildlings: A Practical Guide to Implementing Standards.

Most facilities managers are now familiar with ASHRAE 188-2015 which mandates that everyone with responsibility for centralized water systems-owners, corporate managers, operators and facility managers-must proactively reduce and prevent legionella growth. RK Water provides chemical treatment programs that can be added to existing water treatment programs to reduce the odds of legionella.

We also offer innovative non-chemical technologies like Silver Bullet which uses biocide oxidizers, known as hydroxyl radicals, to kill bacteria and maintain it at low and safe levels-even more effectively than chlorine. In a 2012 University of Pittsburgh study, Silver Bullet™ reduced free-floating legionella bacteria concentration by 78.1{daeb8d662f58e4975bc93960761d671bdf0aa2ad049ea8a375d2717d280ef80b}. It also reduced free-floating Heterotrophic Plate Count (HPC) bacteria by 98.8{daeb8d662f58e4975bc93960761d671bdf0aa2ad049ea8a375d2717d280ef80b} and immobile HPC bacteria by 85.9{daeb8d662f58e4975bc93960761d671bdf0aa2ad049ea8a375d2717d280ef80b}. The HPC test measures microorganisms such as bacteria, yeast and mold in drinking water.

Silver Bullet is safe, quick to install and doesn’t require a large capital investment. The equipment is installed at a facility as an adjunct to its existing water system and the facility pays a monthly rental fee. No large equipment to purchase, and RK Water handles installation, service and maintenance. Want to protect your water system from Legionella? Consider Silver Bullet if you prefer a non-chemical, sustainable solution.

By: RK Water

All cooling towers need some type of make-up valve to replenish water lost to evaporation and blow down. Three basic types are available:

-Mechanical

-Electric and,

-Hydraulic

Mechanical valves typically come as standard from the major tower manufacturers and are the most common. They consist of a valve, float arm and float ball. The float ball

positions the arm and the arm acts on a trigger to open and close the valve. The makeup water pressure recommendation is typically 15psi minimum and 50psi maximum. Too little pressure and the valve may not keep up with the flow requirement. Too much and the valve may pin the float ball ‘down’ and force the valve open.

Electric valves are not very common. There are manufacturers such as Magnetrol that make float switches for 120v but most ‘electric’ valves are more correctly described as ‘electronic’. The reduced voltage lessens the shock hazard, should someone bump into a water level probe while inside the cooling tower. The most common electronic make-up valve is made by ‘Warrick’ and a Google search will yield more info than this short description can provide. The probe can be mounted inside the tower, surrounded by a stilling chamber to subdue the wave action of the water or, in a simple vertical pipe (typically 2″) outside the tower and equalized to the tower cold water basin at the bottom.

Three vertical, ¼” diameter, stainless steel probes point down into the water. The first is cut to nearly reach the basin floor, the second at the level where the make-up valve comes on and the third probe at the level where the make-up valve shuts off. Additional probes can be provided to indicate ‘high’ or ‘low’ water conditions but the three probes described form the basic probe assembly. The three probes are wired to a controller which includes a control relay that directs 120v to a solenoid valve in the make-up line. Such systems are more prone to water hammer than the other types, due to the quick acting nature of the make-up solenoid valves.

Three vertical, ¼” diameter, stainless steel probes point down into the water. The first is cut to nearly reach the basin floor, the second at the level where the make-up valve comes on and the third probe at the level where the make-up valve shuts off. Additional probes can be provided to indicate ‘high’ or ‘low’ water conditions but the three probes described form the basic probe assembly. The three probes are wired to a controller which includes a control relay that directs 120v to a solenoid valve in the make-up line. Such systems are more prone to water hammer than the other types, due to the quick acting nature of the make-up solenoid valves.Hydraulic valves like the ‘Griswold’ have a small pilot valve with a float ball that mounts inside the tower with a stilling chamber, or outside in a stand pipe. The pilot valve connects to the body of the main make-up valve by ¼”copper or plastic tubing. The pilot directs city water pressure to the underside of a diaphragm in the main valve, opening it when the float is ‘down’ and releases the pressure when the float ball is ‘up’, causing the main valve to close. This is probably the best make-up arrangement. It is dependable and acts slowly so as to eliminate water hammer. No electrical connections are required.

[For those familiar with changing the float assembly in a toilet tank, two choices are typically available at the hardware store… The type with a ball about 4″ in diameter on a float arm and another with a smaller float that slides up and down on a pole. The first is a mechanical valve and the second is a hydraulic valve.]