Fire alarm systems are an important investment in your building. Whether you’re looking to design a new system or replace an old one, it’s hard to know who to turn to for the best, most qualified service. You’ve likely come across fire alarm technicians and electricians in your search for a partner, but which is better to take care of your fire alarm system? If you get it wrong, the results could be physically and financially disastrous.

Certification requirements can overlap in some areas, but there are distinct differences due to the specialized nature of fire alarm systems. Let’s see how fire alarm technicians and electricians differ.

What’s the difference between a fire alarm technician and an electrician?

– Scope: Electricians work with various electrical systems, including wiring, lighting, power distribution and HVAC systems. Fire alarm technicians focus specifically on fire alarm systems, which involve installing, maintaining and repairing components such as smoke detectors, control panels, notification devices and communication systems.

– Certification Focus: Any fire alarm technician should have earned their NICET Fire Alarm Systems certification or NFPA 72 certification. To handle their expanded scope of work, fully certified electricians like those at RK Electrical need certifications that go above and beyond what’s needed for fire alarm systems. This offers the ability to have one partner for all your needs rather than multiple partners.

– Training Emphasis: Fire alarm technicians receive specialized training solely focused on fire alarm technology and compliance with fire safety regulations. On the other hand, electricians undergo that training and more to focus on a number of other services such as safety protocols, electrical theory and building codes.

– Regulatory Requirements: Both electricians and fire alarm technicians must comply with regulatory requirements, but the specific regulations they must follow can differ. Electricians must adhere to electrical codes set by organizations such as the National Electrical Code (NEC). Fire alarm technicians must comply with fire codes and standards established by organizations like the National Fire Protection Association (NFPA).

Which is better for designing, installing and servicing my nonresidential fire alarm system?

Electricians have a wider skillset and abilities to work on multiple systems while fire alarm technicians are more narrowly focused and specialized. But what if you could have a partner with the certifications required for both electricians AND fire alarm technicians? That’s what makes RK Electrical the clear choice for businesses in the Colorado Front Range.

RK Electrical’s experts aren’t simply fire alarm technicians; they’re fully certified electricians. We’re proud to have earned certifications by Pikes Peak Regional, Denver Blue Card and NICET 1, 2 and 3. Our commitment to continuing education means our team will always be current with the certifications needed to be your sole partner. For example, a fire alarm technician can’t troubleshoot your system if they find an issue during routine maintenance or inspection. You’ll need to consult an electrician, but why complicate your project with multiple companies when you can use one? Our comprehensive certifications give you the benefit of a turnkey solution, no matter what the unexpected brings.

How RK Electrical can help

RK Electrical can design, install, replace, upgrade, test and maintain AES radios. We handle everything from recommending electrical devices to running wire and installing conduit and raceways to provide comprehensive services that your system needs to function at its best, including:

– Electrical components, such as device terminations, copper conductors and distribution boards.

– Physical hardware like metal conduit, mounting brackets and raceways.

– Commissioning and inspection services for reliability assurance.

We work on any brand, including popular fire alarm systems like Notifier from Honeywell and EST by Edwards. To keep you confident, we also provide a service warranty that includes testing and maintenance for one year.

Why you can trust us

RK Industries is a family business with roots tracing back to 1963. Established in 2015 as part of RK’s continuously expanding construction services, RK Electrical has become a leading commercial electrical contractor that specializes in the installation and maintenance of fire alarm networks for a wide variety of customers.

How to get started

Let’s have a conversation! Contact us to review your needs and see how we can partner to keep your people and property safe.

Fire alarm systems are indispensable safeguards, providing early detection and crucial alerts that can save lives and mitigate property damage. When it comes to relying on a commercial fire alarm system to protect your building’s occupants, there can be no compromises on quality or service. Here are the top five things to consider when evaluating the best fit for your business’ fire alarm system.

1. Detection methods

Fire alarm systems can use various detection methods, and one size or type does not fit all. Do you need smoke detection, heat detection or a combination of both? Should you have a conventional analog system or an addressable digital system? Consider the environment where the system will be installed and choose the appropriate detection method. For example, photoelectric smoke detectors are effective for detecting smoldering fires, while ionization smoke detectors are better at detecting flaming fires. Not sure what you need? RK Electrical can help with that.

2. Reliability and scalability

Look for a fire alarm system from a manufacturer that’s known for producing reliable and high-quality products, such as Edwards, Honeywell, Siemens, Bosch, Simplex and Potter. The system should have built-in redundancies and fail-safes to minimize the risk of false alarms or system failures. It’s also crucial that your fire alarm system can adapt to your needs and be easily expanded or upgraded to accommodate changes in your building layout or occupancy requirements.

3. Compliance with standards and regulations

Verify that the fire alarm system complies with relevant standards and regulations, such as National Fire Protection Association (NFPA) codes and local building codes. Compliance ensures that your fire alarm system meets the minimum safety requirements and may be necessary for insurance purposes.

4. Ease of use and maintenance

Choose a fire alarm system that is user-friendly and easy to maintain. Intuitive interfaces, clear documentation and accessible maintenance procedures make it easier for facility managers to operate and manage the system effectively.

5. Integration with other systems

Consider whether you need your fire alarm system to integrate with other building systems, such as HVAC, access control or surveillance systems. Integration can provide additional functionality and streamline operations, but it requires compatible systems and proper configuration.

How RK Electrical can help

Fire alarm systems are an investment in your building. Do you have a trusted, certified partner to make sure you’re protected in an emergency and compliant with all current codes and standards? RK Electrical’s experts aren’t simply fire alarm technicians; they’re fully certified electricians. We’re proud to have earned certifications by Pikes Peak Regional, Denver Blue Card and NICET 1, 2 and 3. Our commitment to continuing education means our team will always be current with the certifications needed to be your sole partner.

RK Electrical can design, install, replace, upgrade, test and maintain AES radios. We handle everything from recommending electrical devices to running wire and installing conduit and raceways to provide comprehensive services that your system needs to function at its best, including:

– Electrical components, such as device terminations, copper conductors and distribution boards.

– Physical hardware like metal conduit, mounting brackets and raceways.

– Commissioning and inspection services for reliability assurance.

We work on any brand, including popular fire alarm systems like Notifier from Honeywell and EST by Edwards. To keep you confident, we also provide a service warranty that includes testing and maintenance for one year.

Why you can trust us

RK Industries is a family business with roots tracing back to 1963. Established in 2015 as part of RK’s continuously expanding construction services, RK Electrical has become a leading commercial electrical contractor that specializes in the installation and maintenance of fire alarm networks for a wide variety of customers. We provide a turnkey solution that Colorado Front Range businesses trust to be the single partner for all their needs.

How to get started

Let’s have a conversation! Contact us to review your needs and see how we can partner to keep your people and property safe.

In the realm of water treatment, one size does not fit all. Different water sources present unique treatment challenges, whether it’s municipal wastewater, industrial effluent or natural groundwater. This is where the art of custom fabrication in water treatment equipment shines, offering tailored solutions to meet specific needs and ensure clean, safe water for all. Whether it’s a specialized addition to an existing treatment system or fabrication of an entire treatment system, custom fabrication offers tailored solutions to meet specific needs and ensure that water discharges are clean and safe for all.

The process of custom fabrication in water treatment begins with a comprehensive assessment of the water source and the contaminants it contains. This initial analysis is crucial for determining the appropriate treatment technologies and designing systems that can effectively remove impurities and meet regulatory standards.

One of the key advantages of custom fabrication is its ability to accommodate a wide range of treatment technologies and configurations. From traditional methods like filtration and disinfection to technologies such as membrane separation and advanced oxidation, custom-fabricated equipment can be designed to integrate the most suitable processes for each unique application. Moreover, custom fabrication allows for flexibility in design and sizing to optimize performance and efficiency. Whether it’s a small-scale system for a rural community or a large-scale plant for an industrial facility, custom-fabricated systems can be tailored to meet the specific capacity and space constraints of each project.

Furthermore, custom fabrication of water treatment systems offers long-term cost savings by maximizing operational efficiency and minimizing downstream operational costs. By designing a treatment that is specifically tailored to the application, optimal performance and reliability are achieved.

In addition to technical advantages, custom fabrication also enables greater customization in terms of aesthetics and integration with existing infrastructure. Whether it’s matching the equipment to the surrounding environment or seamlessly integrating it into an existing facility, custom-fabricated systems can be designed to meet the aesthetic and functional requirements of each project.

Overall, the art of custom fabrication in water treatment systems represents a powerful tool for addressing the diverse challenges of water treatment and ensuring water is clean and safe for communities and industries around the world. By combining technical expertise with creativity and innovation, custom-fabricated water treatment equipment offers tailored solutions to deliver maximum performance, efficiency and reliability, paving the way for a healthier and more sustainable future.

Contact RK Water today to discuss your water treatment needs.

The construction industry is experiencing robust growth driven by increasing urbanization, infrastructure development and technological advancements.

These trends have increased the demand for skilled professionals across various construction disciplines–from civil engineering and architecture to project management and sustainable design; the avenues for career progression are diverse and enticing.

However, along with these opportunities, the construction sector has unique challenges that one must navigate. Tight project timelines, budget constraints, safety concerns and regulatory compliance are some of the few hurdles that professionals encounter.

Developing Essential Skills for Success

As the industry becomes increasingly complex and interconnected, mastering these essential skills is paramount for professionals aiming to rise above the competition.

1. Technical Skills

Whether operating heavy machinery, fine-tuning architectural designs or executing intricate electrical installations, a solid foundation in technical skills ensures efficiency, precision and safety.

Keeping pace with emerging technologies, such as Building Information Modeling (BIM) software or the use of drones on site, empowers you to work smarter and stay ahead of the competition.

2. Project Management Skills

Proficiency in project management methodologies ensures projects are executed on time and within budget, and fosters a culture of accountability and transparency.

Adept project managers anticipate challenges, mitigate risks and adapt seamlessly to changing circumstances, safeguarding project outcomes and client satisfaction.

3. Communication Skills

Construction is a collaborative endeavor that demands effective communication across diverse stakeholders. The ability to convey complex technical information clearly and concisely bridges the gap between architects, engineers, contractors, clients and regulatory authorities.

Transparent communication ensures alignment of expectations, minimizes misunderstandings and fosters a harmonious working environment.

4. Leadership Skills

As you rise the career ladder, cultivating leadership skills becomes indispensable. Effective leaders inspire their teams, demonstrate unwavering integrity, and lead by example.

They make well-informed decisions under pressure, using the collective expertise of their teams to overcome challenges. In addition, a true leader empowers their colleagues to excel, fostering a culture of growth and continuous improvement.

Pursuing Relevant Education and Training

Earning a degree in construction management or a related field provides a detailed overview of project planning, cost estimation, risk management and other vital aspects of the industry.

Online courses and certifications allow one to acquire specialized skills that can launch your career to new heights. For example, Building Information Modeling (BIM) and Leadership in Energy and Environmental Design (LEED) offer targeted insights directly applicable to the construction landscape.

After having the necessary skills, on-the-job training and apprenticeships (hyperlink to RK Apprenticeship Program page) provide hands-on experience that you can’t replicate in a classroom. Working alongside experienced professionals exposes you to the complexity of construction processes, safety protocols and the art of problem-solving.

Amidst getting hands-on training, construction professionals must embrace a culture of continuous learning to remain relevant and effective.

Building a Strong Professional Network

Industry events, workshops and conferences are vibrant hubs of knowledge exchange, innovation and networking. Also, construction associations and online forums provide ground for networking and collaboration.

By joining reputable organizations like the Associated Builders and Contractors (ABC) (hyperlink), American Institute of Constructors (AIC) or the Construction Management Association of America (CMAA), you can access a network of industry peers, mentorship opportunities and resources to enhance your career trajectory.

In addition, platforms like LinkedIn, Twitter and Instagram offer construction professionals an avenue to showcase their expertise, engage with thought leaders, and connect with potential collaborators.

Setting Clear Career Goals

A construction project requires a well-defined plan to ensure its successful completion. Short-term goals provide the building blocks, allowing professionals to make incremental progress and cultivate necessary skills.

On the other hand, long-term goals offer a broader perspective, guiding professionals towards milestones such as project management roles or leadership positions.

As a construction professional, identify the technical, leadership and soft skills necessary for your desired role. Mapping out how to acquire these skills through education, training and on-the-job experiences forms the cornerstone of your career advancement.

Also, regularly reassess your goals to help you respond to changing circumstances, emerging opportunities and personal growth. Periodic evaluations provide insights into your progress, enabling you to make necessary adjustments to stay on course.

Gaining Experience and Exposure

The construction industry is a vast landscape with many disciplines, each with unique setbacks. Seeking diverse job opportunities within this ecosystem enriches your skillset and enhances your adaptability and problem-solving capabilities.

Volunteer for projects that stretch your capabilities to showcase your commitment to personal growth and willingness to step out of your comfort zone. For instance, cross-functional and cross-departmental assignments are invaluable opportunities for construction professionals to broaden their horizons and cultivate a holistic perspective.

Don’t forget to compile a portfolio highlighting your contributions, showcasing innovative solutions and demonstrating the impact of your work. This strategy will garner attention among employers, making it the start of your career in the construction industry.

Adapting to Technological Advancements

Adapting to technological innovations is no longer an option – it’s a necessity. Building Information Modeling (BIM) has revolutionized the construction industry. It facilitates efficient planning, visualization and collaboration throughout the project lifecycle.

The construction management software also streamlines processes and fosters transparency. This integration allows professionals to optimize resource allocation, track progress in realtime and mitigate potential risks. Also, embracing automation can reduce labor costs, increase safety and accelerate project timelines.

Excel in Safety Practices

Safety is a commitment to the well-being of workers, the protection of assets and the preservation of reputation. Obtaining certifications such as the Occupational Safety and Health Administration (OSHA) 30-Hour Construction Training or the Construction Health and Safety Technician (CHST) designation demonstrates a deep understanding of safety protocols and regulations.

Staying updated with safety regulations and guidelines ensure construction workers remain well-versed in the latest safety protocols. By fostering a culture where safety is ingrained in every action and decision, construction professionals create an environment that minimizes risks and maximizes productivity.

Showcase Soft Skills

Construction sites are dynamic ecosystems where diverse personalities, opinions and interests converge. Proficiency in conflict resolution techniques – active listening, empathy and negotiation–eases tensions and paves the way for constructive collaboration.

In addition, effective problem-solving and decision-making under pressure keep projects on track amidst uncertainty. By showcasing a knack for innovative problem-solving, you position yourself as a reliable anchor, ready to guide projects through turbulent seasons to successful completion.

Becoming Familiar with Sustainable Practices

Green construction principles embody the shift in how projects are conceived, planned and executed. By prioritizing environmental responsibility, construction professionals can create structures that minimize their ecological footprint.

Leadership in Energy and Environmental Design (LEED) certification is a gold standard for sustainable construction. Understanding LEED and its various certification levels equips professionals with the tools to design and execute projects that comply with the highest environmental standards.

LEED-certified buildings prioritize energy efficiency, reduced water consumption, improved indoor air quality and other sustainable attributes. Also, embracing sustainable materials reduces resource depletion and promotes eco-friendliness.

Experience RK

RK Industries offers manufacturing, fabrication, construction and building service solutions. In addition, we are education contributors, offering career development programs to solve the industry’s labor shortage and grow our employee’s careers. Contact us today for more information on how to build your career with RK.

Early civilizations relied heavily on surrounding natural materials like stone, clay, wood and straw to construct shelters and buildings. Ancient civilizations, such as the Egyptians, Greeks, and Romans, mastered the art of masonry, employing locally available stones to create structures that have withstood the test of time.

However, in the 20th century, the construction industry saw a seismic shift as workers embraced synthetic materials. The use of concrete was further improved with the invention of reinforced concrete, combining steel’s strength with concrete’s moldability. This breakthrough opened up endless possibilities in architectural design and structural engineering.

As we venture into the future, the construction industry is poised to embrace strong, durable, efficient and adaptable materials. The potential of construction materials is boundless, from self-repairing structures to energy-neutral buildings.

The 4 Latest Trends in Construction Materials

As the world grapples with environmental challenges, it seeks more efficient building solutions. New materials are emerging, promising to revolutionize how we construct and inhabit buildings.

1. Sustainable Materials

The construction industry is embracing sustainable materials that minimize the ecological footprint of buildings. Recycled aggregates, such as crushed concrete and reclaimed asphalt, reduce the demand for virgin materials and divert waste from landfills. Also, recycled plastic is finding its way into construction products like insulation materials, roofing tiles and formwork systems.

2. Lightweight Materials

Advancements in lightweight materials offer enhanced strength and efficiency. Carbon fiber-reinforced polymers (CFRP) are replacing conventional materials in some structural components to construct lighter and more resilient structures.

Another lightweight material is graphene. This two-dimensional material, derived from graphite, possesses exceptional mechanical properties, such as high tensile strength and flexibility. Graphene-enhanced materials exhibit improved durability, conductivity and fire resistance performance.

3. Self-healing Materials

By incorporating microcapsules or vascular networks within the material matrix, self-healing capabilities can be activated when damage occurs. For example, microcapsules filled with healing agents in concrete can rupture upon cracking, releasing materials that react with the environment to repair the damage.

This technology improves the durability and resilience of structures, reducing the need for frequent repairs and increasing their lifespan. Self-healing materials are also being explored in coatings, metals and polymers, enabling structures to repair themselves in response to external stressors.

4. 3D Printing

3D printing technology enables the fabrication of custom construction materials and components with greater precision and efficiency. Additive manufacturing techniques, such as large-scale 3D printing, allow creating complex geometries, reducing material waste and construction time.

3D printing technology also enables optimizing material usage, offering design freedom. This technology directly integrates functional features, such as embedded sensors, insulation and plumbing systems, into the printed elements, streamlining the construction process.

How Are These Trends Changing the Construction Industry?

The construction industry is undergoing a transformative phase, driven by the adoption of new materials and technologies. Other ways the latest trends in construction materials are revolutionizing the industry and addressing critical challenges include the following:

1. Making Buildings More Environmentally Friendly

Sustainable materials make buildings eco-friendly by reducing reliance on non-renewable resources and minimizing waste generation. Adding recycled aggregates and plastic in construction diverts waste from landfills and saves energy that would have been used when producing new materials.

2. Making Buildings More Efficient and Durable

Lightweight materials, such as carbon fiber and graphene, offer high strength-to-weight ratios, enabling the construction of lighter structures without compromising strength or safety. By reducing the weight of structural components, buildings will require less energy for transportation, assembly and foundation support.

In addition, self-healing materials minimize the need for frequent repairs and maintenance, resulting in longer-lasting structures, reducing resource consumption and waste generation.

3. Making Buildings More Customizable:

3D printing technology has opened up new possibilities for customization in the construction industry. With 3D printing, architects and designers can create complex geometries and unique shapes that were previously challenging or costly. This customization capability allows buildings to be designed to specific needs, aesthetics and site conditions.

Also, construction workers can include plumbing systems, insulation and other building components during construction. The ability to embed functionality within the printed elements streamlines the construction process and reduces the need for additional assembly.

4. The Ethical Implications of Using New Materials

As new materials emerge, it’s essential to evaluate the environmental impact, social implications and long-term sustainability. Using advanced materials may require changes in manufacturing processes or specialized skills, which can impact labor practices and worker training.

Examples of How These Trends are Used in Real-World Projects

The Bullitt Center has numerous sustainable materials, including FSC-certified timber, recycled steel and high-performance glass. The building also uses salvaged materials and features an innovative rainwater harvesting system, solar panels, and geothermal heating, making it one of the greenest commercial buildings in the world.

The Bridge Pavilion is an impressive example of using lightweight materials for temporary structures. The pavilion, designed by Zaha Hadid Architects, utilized carbon fiber for its innovative and lightweight roof structure, allowing for a visually striking, efficient and transportable design.

The ongoing construction of the Basilica of the Sagrada Familia incorporates self-healing concrete technology. The concrete used in the basilica contains microcapsules filled with calcium carbonate, which can rupture and release healing agents when cracks occur.

Dubai’s “Office of the Future” became the world’s first 3D-printed office building. The building was constructed layer by layer using a combination of reinforced concrete and a 3D printer, reducing material waste and construction time.

The Future of Construction Materials

The demand for sustainable construction materials will continue to rise in the next 10 -20 years, driven by the urgency to address climate change and reduce the industry’s environmental impact. We expect wider adoption of materials with low carbon footprints, self-healing materials and 3D printing.

RK is committed to contributing to a brighter, greener future. We operate out of Colorado, Arizona, New Mexico, and Utah with different business units, including Mechanical, Service, Water, Energy, Mission Critical, Steel, and Electrical. Contact us today to learn how we can help you achieve sustainable goals.

The concept of net zero commercial buildings is emerging as a promising solution in the face of escalating environmental concerns and the need to combat climate change. A net zero energy building, also known as a zero energy building, is a structure that generates as much energy as it consumes annually.

Net zero energy buildings decrease reliance on fossil fuel-based energy sources and the grid. As a result, these energy efficient buildings can produce on-site renewable energy, promoting energy independence and reducing vulnerability to energy price fluctuations and electricity grid disruptions.

This sustainable and responsible approach to energy usage encourages long-term cost-savings and enhances indoor comfort and health due to efficient design features, like advanced ventilation systems.

The Three Pillars of Net Zero Energy Buildings

Achieving a net zero energy building involves a comprehensive approach that revolves around these three key pillars.

1. Reduce Energy Demand

To reduce energy consumption, incorporate energy-efficient technologies and equipment, such as LED lighting, high-efficiency HVAC systems and Energy Star-rated appliances. Also, the building’s design should be airtight and well-insulated to prevent energy leakage.

Maximize natural light through large windows, skylights and light shelves. Together, with thoughtful ventilation design, the building can reduce reliance on artificial lighting and mechanical ventilation systems.

2. Generate Renewable Energy

Install photovoltaic (PV) panels to convert sunlight into electricity, offsetting grid electricity consumption. For suitable locations, install wind turbines to harness wind energy to generate electricity for the building.

Also, depending on the available resources, you can employ other renewable energy technologies such as geothermal heat pumps, biomass boilers or micro-hydro systems to generate clean energy.

3. Offset any Remaining Emissions

Invest in verified carbon offset projects to balance any remaining carbon emissions after implementing energy efficiency measures and renewable energy systems. These projects can include renewable energy generation projects or energy efficiency programs.

Greenhouse gas emissions can also be reduced by supporting and investing in renewable energy projects. These projects involve developing and deploying clean energy technologies such as solar, wind, geothermalor hydroelectric power.

The Steps to Achieving Net Zero Energy

Attaining net zero energy is a transformative process requiring careful planning, meticulous design, skillful construction and diligent operation and maintenance. By following a structured approach, buildings can optimize their energy performance and strive towards producing the same energy consumed.

1. Planning and Design

It’s vital to foster collaboration among architects, engineers and energy consultants to create a net zero energy building. This multidisciplinary approach ensures all aspects of energy efficiency and renewable energy integration are considered.

During planning, the design team carefully factors the building’s orientation and site analysis. A well-designed site layout can maximize solar exposure for renewable energy systems, enable efficient natural ventilation and leverage natural features for energy optimization.

In addition, strategic placement and design of glazing elements like windows can minimize unwanted heat gain or loss. Energy modeling tools can help determine the optimal size, type and placement of fenestration to balance daylighting and thermal performance.

2. Construction

To guarantee the success of your project, it is important to prioritize the use of high-quality insulation materials such as spray foam, cellulose or rigid foam boards. These materials should be installed properly on walls, roofs and floors, making it crucial to work with a skilled and vetted professional contractor.

Quality assurance measures and testing are essential throughout the construction process to verify that the building components and systems meet the design’s specifications. It may involve blower door tests to measure air leakage, thermographic inspections to identify insulation gaps or commissioning processes to ensure proper system functionality.

Close collaboration between the design team and the contractor will ensure the design intent is effectively translated into the built form. Regular communication addresses any challenges or discrepancies during construction, ensuring the building meets the energy performance goals.

3. Operation and Maintenance

Once a net zero energy building is completed, ongoing operation and maintenance practices ensure optimal energy performance and minimize energy consumption. For instance, HVAC maintenance includes cleaning or replacing air filters, checking and adjusting thermostat settings, inspecting ductwork for leaks and verifying proper airflow.

Periodically reassessing the building’s energy performance, exploring new technologies or strategies and implementing upgrades as needed can also help optimize energy efficiency over time. Stay informed about advancements in energy-efficient practices and incorporate them into the building’s operation and maintenance plans to contribute to continuous improvement.

By implementing effective operation and maintenance practices, building owners and operators can ensure their net zero energy buildings perform at their highest efficiency levels.

RK Can Help You Achieve Net Zero Buildings

Creating net zero energy buildings requires an approach focusing on reducing energy demand, generating renewable energy and offsetting any remaining emissions.

With the expertise and guidance of companies like RK Mechanical–a business unit for the RK Industries, the journey towards net zero energy is more accessible. RK Mechanical can assist in every step of the process, from the initial planning and design phase to the construction and operation of the building.

By collaborating with RK Mechanical, you can benefit from our expertise in selecting energy-efficient materials, optimizing building design, incorporating renewable energy systems, and ensuring efficient operation and maintenance. Our commitment to sustainability and innovation will help you navigate the complexities of net zero energy buildings and achieve your energy performance targets.

Build a Sustainable Future with RK

RK specializes in creating energy-efficient and environmentally friendly buildings, including net zero energy. Our team of architects, engineers and energy consultants work collaboratively to deliver exceptional results, ensuring you achieve your energy goals while minimizing the environmental impact.

Contact us today to explore our expertise in net zero energy buildings and discover how we can help you achieve your energy goals. Together, let’s create a greener, more efficient world.

In the modern world, access to safe and clean water is fundamental to public health and overall well-being. In the early 1900’s, Chlorination emerged as a water treatment process that revolutionized how we purify and disinfect water on a large scale. The impact of chlorination on society has been profound, drastically reducing waterborne diseases and saving countless lives. In this blog, we will dive into the science behind chlorination, understanding how this ubiquitous disinfection method works to safeguard our water supply.

The Need for Water Treatment

Before the advent of water treatment, communities were plagued by waterborne illnesses such as cholera, E.coli, typhoid and dysentery. These illnesses could and did spread rapidly, devastating entire populations. To address these public health concerns, two pioneering individuals developed the first water treatment plant to establish the delivery of safe drinking water to homes and businesses.

Chlorination is a Game-Changing Discovery

In 1908, a monumental breakthrough occurred when bacteriologist John L. Leal and engineer George W. Fuller introduced the practice of chlorination at the Jersey City Water Supply Company’s Boonton Reservoir in Jersey City, New Jersey, in the first large-scale chlorination of a public drinking water supply in the United States. Initially met with opposition from city officials and the public based on adding “poisonous” chemicals to the drinking water supply, Leal and Fuller persisted, convinced of the potential benefits to the public.

This marked the beginning of an era that would significantly alter the landscape of water purification and serves today as the basis for water treatment purification. By the 1920s, chlorination was a well-established primary means of disinfecting drinking water nationwide.

Today, millions of Americans have access to safe, affordable and abundant drinking water filtered and safely treated with chemical disinfectants due to Leal’s and Fuller’s pioneering engineering triumph.

Mechanism of Chlorination

Chlorination involves the addition of chlorine, either in the form of chlorine gas, sodium hypochlorite (liquid bleach), or calcium hypochlorite (solid granules), to water sources. Upon introduction, the chlorine reacts with various organic and inorganic substances in the water.

Formation of Hypochlorous Acid (HOCl):

Chlorine gas reacts with water (H2O) to form hypochlorous acid (HOCl) and hydrochloric acid (HCl). Hypochlorous acid is the active and most effective form of chlorine for disinfection.

Cl2 + H2O → HOCl + HCl

Disinfection Process:

Hypochlorous acid acts as a powerful disinfectant, attacking and destroying harmful microorganisms by penetrating their cell walls and interfering with enzymatic processes essential for survival. This disrupts the microorganisms’ ability to reproduce and spread, effectively neutralizing the threat of waterborne pathogens.

Chlorine Residual:

Maintaining a chlorine residual in the treated water is crucial to ensure continuous disinfection throughout the distribution system. A chlorine residual refers to the small amount of chlorine that remains in the water after the initial treatment. This residual concentration is a protective barrier against potential contamination during water distribution.

Challenges and Concerns

While chlorination has been a transformative and life-saving water treatment technique, some challenges and concerns are associated with its use.

Disinfection Byproducts (DBPs)

The reaction of chlorine with organic matter in water can lead to the formation of disinfection byproducts (DBPs), such as trihalomethanes (THMs) and haloacetic acids (HAAs). Some DBPs have been linked to potential health risks, including an increased risk of cancer. To address this, water treatment facilities have implemented strategies to minimize DBP formation.

Chlorine Resistance

In recent years, certain microorganisms have shown varying degrees of resistance to chlorine, making it necessary to explore alternative disinfection methods or combine chlorination with other treatment processes.

Conclusion

The science behind chlorination has revolutionized public health by providing access to safe and clean water on a large scale. The disinfection power of chlorine has proven pivotal in reducing waterborne diseases and preventing epidemics. Although challenges persist, ongoing research and advancements in water treatment technology will continue to refine the chlorination process, ensuring that future generations enjoy the benefits of safe and potable water.

Visit rk-water.com for more information.

As the air turns crisp and leaves take on autumn hues, the construction industry must adapt to new challenges and hazards with the changing seasons. While the beauty of fall is undeniable, it’s crucial to remain vigilant about safety on the job site. This blog will dive into essential autumn safety and wellness tips tailored specifically for the construction industry.

Slip and Fall Prevention: A Slippery Slope

Slip and fall accidents are a significant concern in the construction industry, especially during autumn. Studies have shown that wet leaves and frost can significantly increase the risk of falls.

Clear Walkways

Wet leaves can create slippery conditions. Make it a point to clear walkways, scaffolds and work areas of wet or decaying leaves. Here’s a guide on how to do it effectively.

Frost Alert

Morning frost can make surfaces like roofs, scaffolds, and ladders particularly slippery. Extra caution is advised during the early hours. Learn more about frost hazards.

Footwear

Opt for boots with slip-resistant soles to minimize the risk of falls. Check out safety standards for recommended footwear.

Dress for the Weather: Layering Up

Flexible Layers

Dress in layers that can be easily added or removed as the temperature changes throughout the day. Here are some layering tips.

Task-Appropriate

Ensure you dress for the occasion and are comfortable while carrying out your tasks. Keep yourself warm and cozy with appropriate clothing that suits your needs.

Lighting the Way: Shorter Days, Dimmer Lights

Well-Lit Areas

Ensure that work areas are adequately lit, especially if you’re working during dawn or dusk. Choosing the right lighting can be a daunting task. However, you can make the process much easier with a few helpful tips.

High-Visibility Clothing

When working in areas with low light or near traffic, it is essential to prioritize safety. To ensure visibility and protection, it is crucial to wear high-visibility clothing.

Equipment Maintenance: Pre-Winter Checks

Damage Inspection

Check tools and equipment for any signs of wear and tear that may have occurred during the warmer months. Here’s a maintenance checklist.

Winterization

Prepare machinery for colder temperatures to ensure they operate efficiently throughout the season. Learn how to winterize your machinery.

Training: Seasonal Hazards and Emergency Procedures

Seasonal Hazards

It’s crucial to equip workers with the necessary skills to recognize and manage the potential hazards of autumn, such as slippery surfaces and strong winds. Proper training can ensure a safe and productive work environment for everyone involved.

Emergency Procedures

Anticipate unforeseen weather conditions, such as early snowfall. Being prepared is key, so consider the steps your team can take to ensure your team and jobsite are ready for any situation.

Mental Health: More Than Just Physical Safety

Supportive Environment

Encouraging a positive work culture and supporting employees can lead to a productive and enjoyable work environment.

Mental Health Resources

Provide resources or avenues for workers to seek help for mental health issues. Here are some recommended resources.

Maintaining Safety and Efficiency

The autumn season presents unique challenges to the construction industry, but we can effectively navigate them with proactive measures and a focus on safety. By taking necessary precautions, construction sites can maintain a safe and productive environment during this beautiful time of year.

Grasping the Gravity of High Suicide Rates in the Construction Sector

Research has shown that the construction industry, which is primarily male-dominated, has one of the highest suicide rates among its workforce. Men have been conditioned by society to suppress their emotions, leading to silent suffering. The industry is well-known for its “tough-guy” persona and emphasis on self-sufficiency, appealing to those with risk-taking tendencies. Nonetheless, this culture can also pose obstacles for those seeking mental health support, warranting sensitivity and consideration.

In addition, construction schedules often require extended work hours and job relocations, resulting in feelings of detachment from loved ones. The physical demands of the job, combined with a sense of isolation, can drive individuals to self-medicate with alcohol, drugs, or opioids, further increasing the risk of suicide.

The Significance of Mental Health in the Workplace

Mental health plays a crucial role in construction sites as it directly impacts the safety and well-being of the crew. A mentally healthy workforce is not only happier but also more productive. Key indicators of mental distress include lethargy, lack of motivation, concentration difficulties or absenteeism.

Promoting mental health and wellness within the workplace can foster a positive atmosphere for employees. As a result, this can aid in retaining and recruiting staff members who are interested in pursuing a career in the construction industry.

Comprehending Mental Health

Maintaining good mental health is an ongoing process. Various factors such as personal loss, financial difficulties and relationship issues can negatively impact a person’s mental well-being and ability to concentrate. In environments with a higher risk, operating heavy equipment or getting distracted due to a lack of focus can be dangerous for both workers and the public.

Encouraging an environment where individuals feel comfortable sharing their personal experiences can empower coworkers to check on their crewmates, thereby fostering a safer workspace for everyone involved.

The Role of Management in Driving Change

As a company, it is important to prioritize the well-being of employees. Creating a sense of community and belonging can be achieved by encouraging everyone to be aware of their surroundings and environment. This is especially important in the construction industry, where transitioning from a culture of discipline to one that prioritizes employee mental health and well-being can make a significant impact.

Leaders and employees can provide essential resources to promote mental health by practicing active listening, compassion and empathy towards one another. This approach fosters a supportive environment that enables everyone to thrive.

Identifying Warning Signs on a Jobsite

When observing individuals, paying attention to their behavior and life circumstances can provide valuable insights into their mental and emotional state. Verbal expressions such as discussing suicide, depression, anxiety or feeling like a burden to others can be red flags. Some behaviors, like being absent often, experiencing a sudden decrease in productivity or engaging in risky actions, may suggest that there are underlying problems.

Additionally, personal stressors such as going through a divorce, losing a job or losing a loved one can all impact a person’s emotional well-being. Awareness of these factors can enhance our understanding and enable us to provide better support.

Implementing Measures to Manage and Prevent Workplace Suicide

Companies can play a crucial role in managing and preventing such incidents by taking proactive steps. One of the most important steps is to identify the warning signs, including changes in mood, social withdrawal, talk of wanting to die or giving away personal belongings. Creating a safe environment where employees can openly discuss their issues and feel supported is essential.

Additionally, providing access to mental health resources and safety guides can help employees deal with such issues effectively. Implementing these measures can help companies establish a safe and supportive environment, significantly decreasing the occurrence of suicide in the workplace.

Fostering a Safe Work Environment

Creating a safe and supportive work environment is vital for the well-being of employees. Encouraging open communication about mental health issues, providing access to resources and professional help, and promoting a culture of support can go a long way in achieving this goal. By taking these steps, we can help prevent suicide and save lives in the construction industry.

Prioritizing Employee Mental Health

At RK, the safety and well-being of our employees is of utmost importance. We prioritize creating a work environment that is physically, mentally and emotionally safe for everyone. Safety is our number one core value and priority. We believe in promoting mental health awareness as an integral part of our culture, whether you work on-site, ina shop or in the office. By providing training, our employees are encouraged to check in with their colleagues to express care for their well-being.

Resources for Mental Health and Suicide Prevention

During difficult times, it’s common to feel isolated and helpless. However, it’s important to recognize that seeking help is a courageous act that demonstrates strength rather than weakness. If you or someone you know is struggling with mental health issues or having suicidal thoughts, remember that assistance is readily available.

Crisis Text Line: Text “Hello” to 741741

National Suicide Prevention Hotline: 988 OR 1.800.273.8255 (English), 1.888.628.9454 (Espanol), 1.800.273.8255 (Deaf and Hard of Hearing)

For more information about mental health and suicide prevention in the construction industry, visit:

- The Construction Industry Alliance for Suicide Prevention

- Construction Financial Management Association

- Construction Working Minds

- Man Therapy

Please note that this blog is for informational purposes only. It should not be used as a substitute for professional medical advice, diagnosis or treatment. Always seek the advice of your healthcare provider with any questions you may have regarding a medical condition or mental health symptom. Never disregard professional medical advice or delay in seeking it because of something you have read on this website.

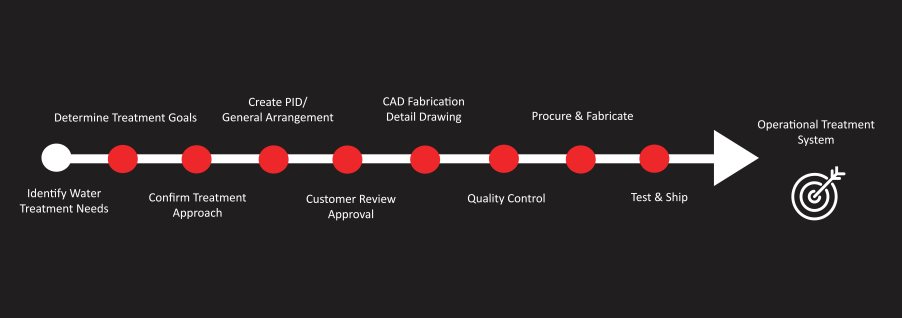

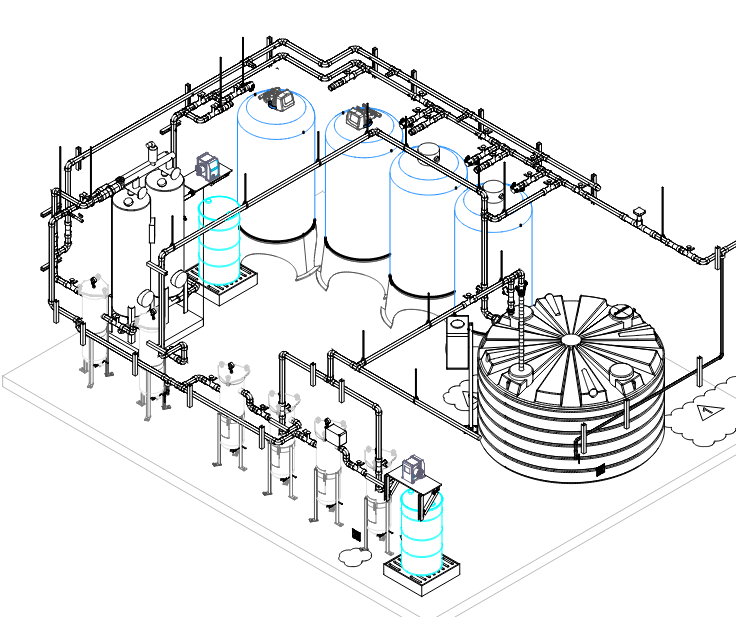

At RK Water, we specialize in providing custom water treatment systems to meet the unique needs of our clients. We take care of every part of the fabrication process, from identifying treatment needs to delivering a fully functional operational water treatment system.

Identifying Water Treatment Needs, Goals and Approach

Every custom water treatment project begins with a thorough assessment of site-specific treatment requirements. By understanding our client’s needs, we design comprehensive water treatment solutions that align with desired outcomes. This includes considering contaminant levels, flow rates, and water quality standards. Our team will engineer a system that meets or exceeds desired standards to meet environmental regulations. Based on the needs and treatment goals, RK Water will explore the best available technologies, such as reverse osmosis, medias, resins and chemical treatment.

Creating Schematic Design and CAD Fabrication Drawing

With the treatment approach determined, our experienced engineers create a schematic design that serves as a blueprint, outlining the treatment system’s layout, equipment arrangement and process flow. Using cutting-edge CAD software, RK Water generates detailed drawings of the fabrication process. These drawings provide precise specifications for each component, including dimensions, materials, connections and assembly instructions.

Procurement, Fabrication and Testing

Our in-house team of plumbers and pipefitters will fabricate the designed water treatment systems. By working with other RK business units, we have the in-house capabilities and facilities to ensure every component is installed correctly and according to the design specifications. Once fabrication is complete and signed off, the completed fabricated system is carefully packaged and prepared for shipping to the installation site.

Operational Treatment System

If desired, the RK Waters field team will install the treatment system upon arrival at the site. Before system operation begins, we’ll ensure that all components are properly connected and calibrated, guaranteeing a smooth start-up sequence. Furthermore, RK Water offers ongoing operational and maintenance services, including technical assistance, to keep the treatment system operating at peak performance.

At RK Water, we understand that each water treatment project is unique and requires a tailored approach. Our fabrication process ensures that our clients’ water treatment goals are effectively and efficiently achieved. If you’re looking for a reliable partner in water treatment, count on RK Water to provide comprehensive solutions.

Learn more at rk-water.com.