In the realm of water treatment, one size does not fit all. Different water sources present unique treatment challenges, whether it’s municipal wastewater, industrial effluent or natural groundwater. This is where the art of custom fabrication in water treatment equipment shines, offering tailored solutions to meet specific needs and ensure clean, safe water for all. Whether it’s a specialized addition to an existing treatment system or fabrication of an entire treatment system, custom fabrication offers tailored solutions to meet specific needs and ensure that water discharges are clean and safe for all.

The process of custom fabrication in water treatment begins with a comprehensive assessment of the water source and the contaminants it contains. This initial analysis is crucial for determining the appropriate treatment technologies and designing systems that can effectively remove impurities and meet regulatory standards.

One of the key advantages of custom fabrication is its ability to accommodate a wide range of treatment technologies and configurations. From traditional methods like filtration and disinfection to technologies such as membrane separation and advanced oxidation, custom-fabricated equipment can be designed to integrate the most suitable processes for each unique application. Moreover, custom fabrication allows for flexibility in design and sizing to optimize performance and efficiency. Whether it’s a small-scale system for a rural community or a large-scale plant for an industrial facility, custom-fabricated systems can be tailored to meet the specific capacity and space constraints of each project.

Furthermore, custom fabrication of water treatment systems offers long-term cost savings by maximizing operational efficiency and minimizing downstream operational costs. By designing a treatment that is specifically tailored to the application, optimal performance and reliability are achieved.

In addition to technical advantages, custom fabrication also enables greater customization in terms of aesthetics and integration with existing infrastructure. Whether it’s matching the equipment to the surrounding environment or seamlessly integrating it into an existing facility, custom-fabricated systems can be designed to meet the aesthetic and functional requirements of each project.

Overall, the art of custom fabrication in water treatment systems represents a powerful tool for addressing the diverse challenges of water treatment and ensuring water is clean and safe for communities and industries around the world. By combining technical expertise with creativity and innovation, custom-fabricated water treatment equipment offers tailored solutions to deliver maximum performance, efficiency and reliability, paving the way for a healthier and more sustainable future.

Contact RK Water today to discuss your water treatment needs.

In the modern world, access to safe and clean water is fundamental to public health and overall well-being. In the early 1900’s, Chlorination emerged as a water treatment process that revolutionized how we purify and disinfect water on a large scale. The impact of chlorination on society has been profound, drastically reducing waterborne diseases and saving countless lives. In this blog, we will dive into the science behind chlorination, understanding how this ubiquitous disinfection method works to safeguard our water supply.

The Need for Water Treatment

Before the advent of water treatment, communities were plagued by waterborne illnesses such as cholera, E.coli, typhoid and dysentery. These illnesses could and did spread rapidly, devastating entire populations. To address these public health concerns, two pioneering individuals developed the first water treatment plant to establish the delivery of safe drinking water to homes and businesses.

Chlorination is a Game-Changing Discovery

In 1908, a monumental breakthrough occurred when bacteriologist John L. Leal and engineer George W. Fuller introduced the practice of chlorination at the Jersey City Water Supply Company’s Boonton Reservoir in Jersey City, New Jersey, in the first large-scale chlorination of a public drinking water supply in the United States. Initially met with opposition from city officials and the public based on adding “poisonous” chemicals to the drinking water supply, Leal and Fuller persisted, convinced of the potential benefits to the public.

This marked the beginning of an era that would significantly alter the landscape of water purification and serves today as the basis for water treatment purification. By the 1920s, chlorination was a well-established primary means of disinfecting drinking water nationwide.

Today, millions of Americans have access to safe, affordable and abundant drinking water filtered and safely treated with chemical disinfectants due to Leal’s and Fuller’s pioneering engineering triumph.

Mechanism of Chlorination

Chlorination involves the addition of chlorine, either in the form of chlorine gas, sodium hypochlorite (liquid bleach), or calcium hypochlorite (solid granules), to water sources. Upon introduction, the chlorine reacts with various organic and inorganic substances in the water.

Formation of Hypochlorous Acid (HOCl):

Chlorine gas reacts with water (H2O) to form hypochlorous acid (HOCl) and hydrochloric acid (HCl). Hypochlorous acid is the active and most effective form of chlorine for disinfection.

Cl2 + H2O → HOCl + HCl

Disinfection Process:

Hypochlorous acid acts as a powerful disinfectant, attacking and destroying harmful microorganisms by penetrating their cell walls and interfering with enzymatic processes essential for survival. This disrupts the microorganisms’ ability to reproduce and spread, effectively neutralizing the threat of waterborne pathogens.

Chlorine Residual:

Maintaining a chlorine residual in the treated water is crucial to ensure continuous disinfection throughout the distribution system. A chlorine residual refers to the small amount of chlorine that remains in the water after the initial treatment. This residual concentration is a protective barrier against potential contamination during water distribution.

Challenges and Concerns

While chlorination has been a transformative and life-saving water treatment technique, some challenges and concerns are associated with its use.

Disinfection Byproducts (DBPs)

The reaction of chlorine with organic matter in water can lead to the formation of disinfection byproducts (DBPs), such as trihalomethanes (THMs) and haloacetic acids (HAAs). Some DBPs have been linked to potential health risks, including an increased risk of cancer. To address this, water treatment facilities have implemented strategies to minimize DBP formation.

Chlorine Resistance

In recent years, certain microorganisms have shown varying degrees of resistance to chlorine, making it necessary to explore alternative disinfection methods or combine chlorination with other treatment processes.

Conclusion

The science behind chlorination has revolutionized public health by providing access to safe and clean water on a large scale. The disinfection power of chlorine has proven pivotal in reducing waterborne diseases and preventing epidemics. Although challenges persist, ongoing research and advancements in water treatment technology will continue to refine the chlorination process, ensuring that future generations enjoy the benefits of safe and potable water.

Visit rk-water.com for more information.

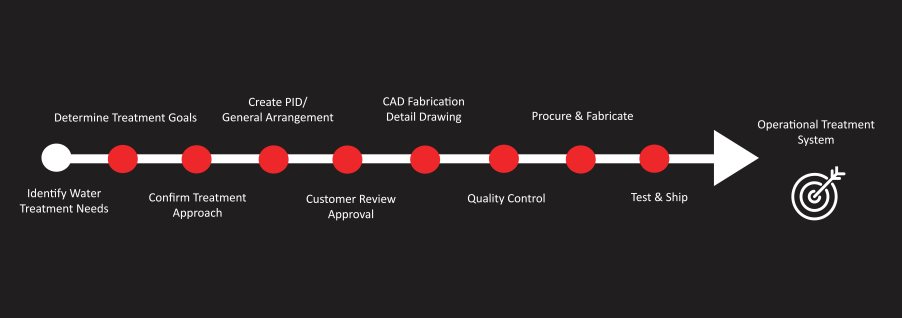

At RK Water, we specialize in providing custom water treatment systems to meet the unique needs of our clients. We take care of every part of the fabrication process, from identifying treatment needs to delivering a fully functional operational water treatment system.

Identifying Water Treatment Needs, Goals and Approach

Every custom water treatment project begins with a thorough assessment of site-specific treatment requirements. By understanding our client’s needs, we design comprehensive water treatment solutions that align with desired outcomes. This includes considering contaminant levels, flow rates, and water quality standards. Our team will engineer a system that meets or exceeds desired standards to meet environmental regulations. Based on the needs and treatment goals, RK Water will explore the best available technologies, such as reverse osmosis, medias, resins and chemical treatment.

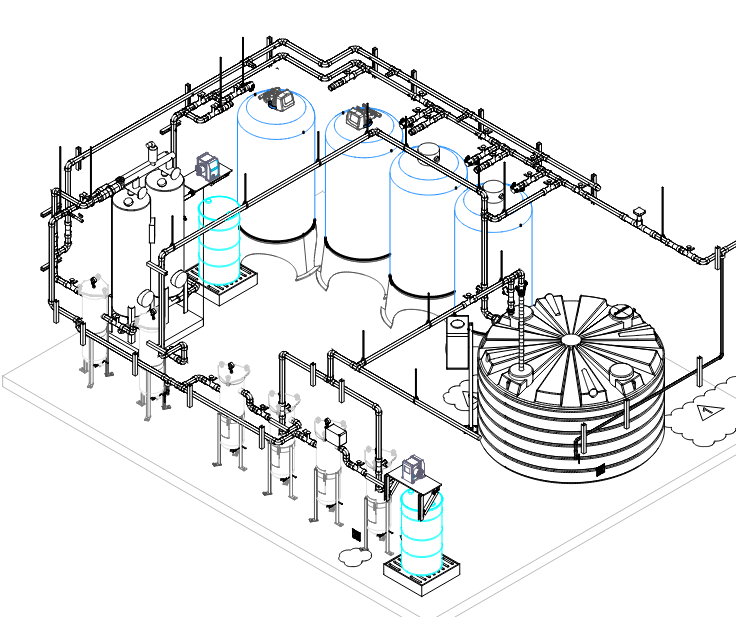

Creating Schematic Design and CAD Fabrication Drawing

With the treatment approach determined, our experienced engineers create a schematic design that serves as a blueprint, outlining the treatment system’s layout, equipment arrangement and process flow. Using cutting-edge CAD software, RK Water generates detailed drawings of the fabrication process. These drawings provide precise specifications for each component, including dimensions, materials, connections and assembly instructions.

Procurement, Fabrication and Testing

Our in-house team of plumbers and pipefitters will fabricate the designed water treatment systems. By working with other RK business units, we have the in-house capabilities and facilities to ensure every component is installed correctly and according to the design specifications. Once fabrication is complete and signed off, the completed fabricated system is carefully packaged and prepared for shipping to the installation site.

Operational Treatment System

If desired, the RK Waters field team will install the treatment system upon arrival at the site. Before system operation begins, we’ll ensure that all components are properly connected and calibrated, guaranteeing a smooth start-up sequence. Furthermore, RK Water offers ongoing operational and maintenance services, including technical assistance, to keep the treatment system operating at peak performance.

At RK Water, we understand that each water treatment project is unique and requires a tailored approach. Our fabrication process ensures that our clients’ water treatment goals are effectively and efficiently achieved. If you’re looking for a reliable partner in water treatment, count on RK Water to provide comprehensive solutions.

Learn more at rk-water.com.

Spring is a great time to consider your facility’s cooling tower system. As the weather warms up, many comfort cooling systems shut down in the late fall and winter will soon be put back into operation. Following a few “good housekeeping” procedures are important before these systems are filled with water and started up. These steps allow facilities managers to save money and avoid headaches during the cooling season.

Step 1: Clean Cooling Tower Fill, Basin and Hot Deck

To prepare a cooling system for the upcoming season, clean the cooling tower fill, basin and hot deck. Dirt and debris from the previous cooling season and winter months can build up and must be removed. Failure to remove this debris can foul and plug system components, leading to poor cooling system performance.

Additionally, debris can be a food source for microbiological growth, which can cause corrosion and fouling of heat exchange surfaces and can lead to airborne pathogens such as Legionella. To avoid these issues, debris should be removed from the hot deck and distribution holes. Any broken sprayers or distributors should be repaired or replaced, and the system should be sanitized before being returned to service.

Step 2: Clean and Calibrate Cooling Water Controller

To ensure the optimal functioning of your cooling systems, it’s crucial to clean and calibrate various components. These include the cooling water conductivity controller, probes, flow switch, level controls and chemical metering pumps. Conductivity, pH, and ORP probes that have not been serviced for several months should be cleaned and calibrated. Chemical metering pumps may also need to be cleaned and primed with fresh chemicals before calibration.

Components not properly maintained during the previous season may need to be repaired or replaced to help your cooling systems run smoothly and efficiently. Check that all parts function correctly to keep the cooling water’s chemical balance and prevent scale buildup and corrosion.

Step 3: Clean and Lubricate Fans and Motors

The final step in preparing for the cooling season is cleaning fan housings, lubricating fans and motors, and checking for oil leaks. Ensure fan belts are tight and in working order and replace them if necessary. Oil leaks in fan motors can foul the cooling water system, reducing heat transfer efficiency and causing microbiological growth.

RK Water can assist with your facility needs by providing maintenance services for cooling tower systems, including cleaning and disinfecting the water tanks, checking and repairing leaks, and ensuring that the system is functioning correctly before the start of the cooling season. RK Water’s expertise can help you save money on energy costs and avoid costly repairs down the line.

PFAS, also known as per- and polyfluoroalkyl substances, are thousands of chemicals belonging to a single chemical class. PFAS contaminants are found in drinking water as a result of industrial releases and the use of firefighting foam. However, PFAS may also be used in a wide range of products, from food packaging to stain-resistant furniture, and our exposure comes from multiple sources and routes. PFAS does not break down in the environment and moves through soil to drinking water, which is why many scientists refer to them as “forever chemicals.”

What products contain PFAS?

Everyday products may be made with PFAS compounds, such as:

• Clothing like raincoats, yoga pants, shoes and accessories

• Paper packaging, including microwave popcorn bags and takeout packaging

• Stain-resistant carpets, rugs and furniture

• Non-stick cookware

• Firefighting foams and ski wax

Exposure to PFAS is virtually everywhere, from food, air and water, resulting from manufacturing releases and use of PFAS-containing products. Fortunately, the United States Environmental Protection Agency (EPA) has been taking active steps to update drinking water health advisories to replace those issued in 2016. The updated advisories indicate that some adverse health effects occur with concentrations of PFAS in water near zero and below the EPA’s ability to detect. Essentially, the lower the level of PFAS chemicals, the lower the risk to public health.

In addition, EPA is encouraging states, drinking water utilities, and community leaders that find PFAS in their drinking water to inform residents, undertake additional monitoring to assess the level, scope, and source of contamination, and examine steps to reduce exposure. Individuals concerned about levels of PFAS in their drinking water should consider actions that may reduce exposure, including installing a home or point-of-use filter.

How to reduce PFAS contamination?

Under the State of Colorado’s guidance, over 100 communities are retesting drinking water to create dilution or treatment plans if PFAS levels are high. The EPA’s drinking water guidance for PFAS was formerly no more than 70 parts per trillion. However, in June 2022, the EPA’s guidance for two forms of PFAS, PFOA and PFOS, was cut to 0.004 parts per trillion and 0.02 parts per trillion, respectively.

While the EPA has only proposed guidelines for PFAS levels in drinking water, states across the country are implementing enforceable drinking water standards and pursuing litigation against manufacturers of PFAS chemicals for contaminating water supplies and other natural resources.

With more data being shared with government entities about PFAS contamination and states adopting more policies to protect their residents, restrictions will get more rigorous to help eliminate PFAS chemicals. Local governments, state governments and businesses need to work together to help protect those in their communities by taking proper action now.

PFAS Chemical Treatment and Disposal

RK Water has the knowledge and expertise to guide your business through treatment selection, system sizing and ongoing operation. As water treatments experts, RK Water will:

• Perform initial PFAS sampling and testing through DOD certified laboratories

• Evaluate the characteristics of the PFAS requiring treatment

• Take into account site-specific conditions, sustainability of the treatment methods, and cost-effectiveness of viable treatment options

• Perform CAPEX vs. OPEX evaluation of competing treatment options

• Design and install temporary or long-term equipment, including treatment media

• Operate and maintain equipment and treatment systems, including media changeouts

• Compliance testing and reporting

• Manage disposal of media

The result is the reliable treatment of PFAS contamination to desired treatment goals. RK Water has you covered with in-house technical expertise. As RK Water is not committed to one proprietary product line, you are ensured that you will receive the best treatment options available in the market and client-focused attention throughout the process.

Learn more about RK Water’s PFAS treatment services.

Written by Ileana Morales

EPA Announces New Drinking Water Health Advisories for PFAS Chemicals, $1 Billion in Bipartisan Infrastructure Law Funding to Strengthen Health Protections, accessed July 29, 2022, Environmental Protection Agency

Get the Facts: PFAS (per- and polyfluoroalkyl substances), accessed July 29, 2022, Safer Chemicals, Healthy Families

South Adams County water district is buying Denver’s water to dilute “forever chemicals,” accessed July 29, 2022, The Colorado Sun

Most people automatically picture a man when thinking of a construction worker. However, women are just as qualified and capable of being successful in the industry. Construction careers require high levels of skill and determination, perfect for anyone who enjoys creating and working with their hands.

Currently, women make up 10.3% of the construction workforce in the U.S. Just two years ago, that number was closer to 9%. While that number has not jumped significantly, it has steadily increased over the past decade.

Although still inadequately represented, 31% of women in the industry hold professional or management roles, many of which have moved into those roles in recent years. This shows that companies have been increasing efforts to promote and educate women about the benefits of working in construction.

Technological advancements, such as hydraulic equipment, have also made brute strength less important to get the job done. Regardless, some men still feel that women cannot carry their share of the workload and some women are concerned they might be considered masculine for working in the industry. Recruitment bias and non-inclusive work cultures also remain a concern.

Despite stigmas, more women are seeing the earning potential and diverse opportunities available in the industry. They are steadily working towards changing views about gender norms and leveling the playing field. Additionally, nearly 87% of women who work in the industry hold office positions, squashing most of the gender concerns.

In recent years, the construction labor shortage has presented an opportunity to hire more women than ever. Diversity is important in solving the labor shortage crisis and research has shown that gender diversity brings economic benefit to companies. Those companies with higher gender diversity in their workforce who have proved to be much more likely to outperform the industry average. Hiring more women in construction is a win-win situation.

Many organizations, like Professional Women in Construction, provide mentorship, networking and opportunities for growth and business development to women in the industry. The goal of Women in Construction Week is to bring awareness to those opportunities, directing interested women to training programs and local mentorship groups, and encouraging women to become role models. By highlighting the value of construction jobs for women, other women and young girls can see the industry as a viable career path.

The RK Apprenticeship Program began an all-female apprentice class last year with great success. If you, or someone you know, is interested in learning more about our apprenticeship program, click here.

The Rise of Women in the Construction Field, National Center for Construction Education & Research, December 3, 2020

How Women in Construction Positively Impact Profits and Collaboration, Digital Builder, March 5, 2020

Just 9.1% of America’s construction workers are women—here’s what it’s like to be one of them, CNBC Make It, January 29, 2019

Women in Construction: The State of the Industry in 2021, Big Rentz, January 19, 2021

By: RK Water

In the second installment of “Understanding Dewatering,” we’re diving into the importance of representative groundwater sampling — one of the most undervalued aspects of temporary dewatering.

According to Pinyon Environmental, “The groundwater chemistry data collected for permit applications is often flawed because the collection techniques don’t adequately mimic the turbidity associated with the various construction means and methods. This results in either an under- or over-representation of the geotechnical impacts. And under-represented geotechnical condition could result in [the] under-design of the treatment system and [introduce] potential project delays and unanticipated costs.”

Groundwater sampling is essential because each of the following behaviors has the potential to distort groundwater treatment requirements by inadequately characterizing the groundwater chemistry:

- Reliance upon one test well for groundwater sampling.

- Only one groundwater sample analyzed for chemistry.

- Inadequate purging of the test well.

Be sure to uplevel the sampling process by taking heed of potential sample biases. A sampling event is merely a description of general chemistry at a specific moment in time. When test wells are installed, not only will the groundwater table vary according to each well, but the chemistry of groundwater will also fluctuate, sometimes drastically. Clay layering, bedrock, and underground rivers are below the surface, which is what causes naturally occurring obstructions; these obstructions can introduce chemistry variances that will be overlooked if only one test well is used.

Sampling activities over an extended period of time will provide a more accurate measurement of fluctuations in the groundwater table and its chemistry. Furthermore, water that is allowed to stagnate with soil, will naturally contain higher levels of heavy metals and other contaminants. Through proper purge procedure, or even extending beyond the minimum, it is possible to obtain lower levels of heavy metals in the sample.

Once dewatering commences, groundwater will begin flowing downstream according to the natural flow of alluvial groundwater. Research also needs to be conducted regarding existing dewatering permits in the vicinity of the project to validate results from sampling activities. More importantly, permits upstream of the project will identify the chemistry to anticipate through continued dewatering activities. In the end, it’s not always about the chemistry of the groundwater within the confines of your shoring, but what’s in your neighbor’s groundwater that may make or break a project.

By: RK Water

The use of steam boilers for industries in the U.S. is essential, especially when you consider they are used in highly monitored industries including food and beverage processing, medical facilities, power generation and sanitation. One of the main components in a successfully functioning steam boiler is the quality of its feed water.

In order to ensure proper operation of steam boilers, high purity water is required. However, through years of experience, RK Water has discovered that the single biggest issue in nonfunctioning steam boilers is poor feed water pretreatment, or, in some instances, no pretreatment at all. This leads to much larger maintenance problems.

TOP 3 REASONS FOR FEED WATER PRETREATMENT IN STEAM BOILERS

- Boiler failures result in operational downtime, repair and cleaning expenses

- Extensive scale deposits require more fuel for steam production

- Hot spots can cause boiler tube corrosion or failure

The evidence of poor pretreatment speaks volumes about the importance of having a scheduled service in place. A good boiler feed water treatment system will help you avoid costly plant downtime, expensive maintenance fees and boiler failures as a result of scaling, corrosion and pollutants in the boiler and downstream equipment.

If you suspect you are having issues with pretreatment, allow RK Water to take a sample of your feed water and run several tests to see what level of hardness is making it to your boiler. Our team can make recommendations, adjustments and even studies and analysis of your current system to see what best meets your needs.

By: RK Water

Before and during the excavation phase, project developers, architects, general contractors and other project partners take many considerations into account when planning the groundwork for a project including soil analysis, solar angles and other site-specific conditions. One of the most overlooked and under-valued planning activities involves an analysis of groundwater on the project site and how it may affect the project. This step is essential; those who skip it are at risk for project shut down or slow down due to unidentified water.

Dewatering is the action of removing groundwater or surface water from a construction site. It’s most commonly performed due to water that has accumulated during excavations or in places with a high water table. In these cases, the water must be removed for safety in order to proceed with construction as scheduled.

So, what’s required to dewater your next project? We will dive into four key pillars in future blogs to include:

- Representative groundwater sampling

- Flow rates and dewatering methodologies

- Permitting – Which one is appropriate to your project?

- Treatment methodologies

With proper planning, treatment of groundwater on construction projects can be a manageable process that allows your timeline to remain on track.

Did you know that RK Water provides temporary and permanent dewatering services? Our team treats a wide variety of water contamination issues in dewatering operations from Total Suspended Solids (TSS) removal to complicated remediation activities. RK Water approaches every project with a high level of engagement leading up to project commencement followed by unmatched field service during dewatering and remediation operations. Contact Steven Cummings at Steven.Cummings@rk-water.com to discuss a groundwater plan for your next project.